Connectors stand out as vital building blocks in the complex world of automobile manufacturing, where each component is vital to guaranteeing the dependability, safety, and performance of vehicles. They serve as a vital interface between the various electrical parts of the car, enabling smooth signal transfer.

Among the various types of connectors available, the 110 series stands out for its reliability, flexibility, and effectiveness. This series holds a significant position in the automotive industry, where the need for strong and trustworthy electrical connections is paramount. From motorcycles to cars and even commercial vehicles like three-wheelers, 110 series connectors play a crucial role in ensuring seamless operations and optimal performance.

110 series connecters is well-known for it strength and dependable in providing electric connecting in automotive applications. Made from good-quality materials like nylon 6, nylon 66, and polypropylene (PP), these connecters brag extraordinary endurance and resistance to environmental factors such as changes in temperature, humidity, an chemical exposure. These toughness guarantees uniform performance, even in the difficulties often faced in automotive settings.

Variants and Configurations:

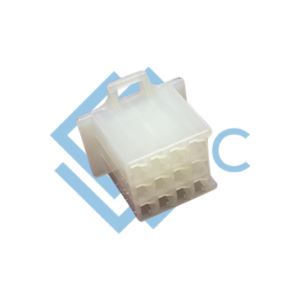

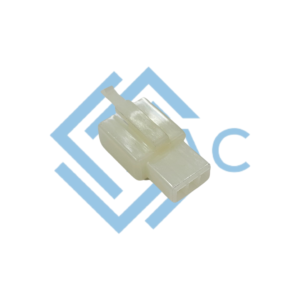

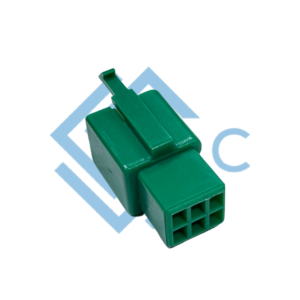

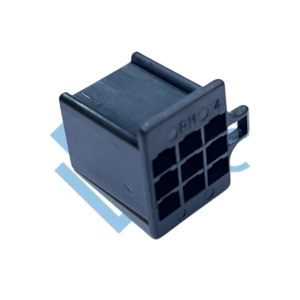

The numerous configurations available for 110 series connectors demonstrate their adaptability in meeting various wiring needs in automobiles. Among these configurations are:

- 1-pole male connector

- 1-pole female connector

- 2-pole male connector

- 2-pole female connector

- 3-pole male connector

- 3-pole female connector

- 4-pole male connector

- 4-pole female connector

- 6-pole male connector

- 6-pole female connector

- 9-pole male connector

- 9-pole female connector

- 12-pole male connector

- 12-pole female connector

There are also special categories of 110 series connector such as 3 pole male and 4 pole male CUT connectors.

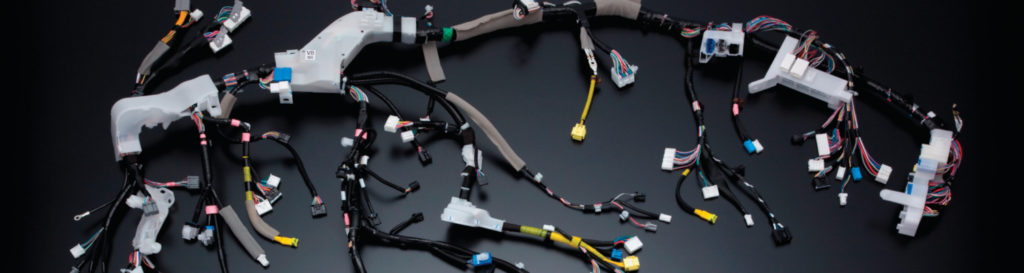

110 series connectors play a pivotal role in the assembly of wire harnesses, which serve as the backbone of a vehicle’s electrical system. By providing secure and reliable connections between various components such as sensors, actuators, lights, and control modules, these connectors enable the efficient transmission of signals and power throughout the vehicle. Their ease of installation and maintenance streamlines the manufacturing process, contributing to cost-effectiveness and operational efficiency in automotive production facilities.

Application in Automobile Wire Harness Manufacturing:

As the cornerstone of a car’s electrical system, 110 series connectors are essential parts of the complex web of wire harnesses. The electrical system of the car is supported by these connectors, which enable the smooth integration of many essential parts such as lights, actuators, sensors, and control modules. Their main job is to create safe and dependable connections so that electricity and signals may continue to flow throughout the car.

These connectors provide strong protection against vibration, moisture, temperature fluctuations, and other difficult situations since they are painstakingly made to endure the demands of automotive settings. This resilience raises the vehicle’s overall dependability and safety by ensuring the electrical connections’ long-term integrity.

To put it simply, 110 series connectors are essential to maximizing the efficiency, dependability, and affordability of vehicle electrical systems. Because of their durable design, simplicity of use, and universal compatibility, they are essential parts of contemporary vehicle manufacture, spurring innovation and progress in the automotive sector.

You save

You save

- Select options This product has multiple variants. The options may be chosen on the product page

You save

- Select options This product has multiple variants. The options may be chosen on the product page

You save